- Main Page

- Age on other Planets

- Aliens

- American Flag

- Annuals

- Avoiding Scams

- Awareness Ribbons

- Baileys Liqueur

- Bananas

- Banana Tree, Grand Nain

- Banana Tree, Ice Cream

- Banana Tree, Zebrina Rojo

- Beekeeping

- Bleach

- Boogaloo

- Bookmarks

- Boot Anatomy

- Boot Fit Guide - Cowboy

- Boot Glossary

- Boot Leathers

- Boot Makers

- Boot Retailers

- Boot Styles - Western

- Boot Toes & Heels - Western

- Boot Toes & Heels - Work

- Bullying

- Cats

- Chillicothe Businesses

- Christmas Tree

- Ciroc Vodka

- Coffee Pods

- Color Codes Chart

- Consumer Resources

- Consumer Resources - Elders

- Country Stars

- Cowboy Hats

- Cowboy Hat Etiquette

- Cowboy Hat Sizing

- Cowboy Sites

- Credit Score Checkers

- Credit Scores

- Disaronno Amaretto

- Donation

- Drug Test

- Eye Teasers

- Fonts

- Foods To Regrow

- Free For All Links

- Friend

- Funny Things

- Fun Stuff

- Giving

- Growing Blueberries

- Halloween

- Halloween Treats

- Health Pages

- Hello!!

- Home Bar

- Horse Sites

- House Plants

- Hunger Facts

- Interesting Facts

- Kinds of Tea

- Logger vs Lineman

- Lucky Bamboo

- Macaroni!!

- Missouri

- Missouri Prisons

- National Foundations

- Never Forget

- New Page Soon

- One Little Rose

- Orchid Growing

- Orchid Sources

- PayPal.Me

- Perennials

- Phobias A-Z

- Plant Care

- Plant Zone Map

- Propagating Plants

- Ragtime Music

- Recipes I like

- Roses

- Sadie & Beethoven

- Scam Calls

- Smile

- Speed Test

- Spices You Need

- Spices I Have

- Steel Toe vs. Comp. Toe

- Superstitions

- Symbols

- Tequila Rose

- The Ten Commandments

- Top Alcohol

- Top Animated Movies

- Top Comedy Movies

- Top Expensive Movies

- Top Modern Westerns

- Top 100 Westerns

- Toyota Yaris 2008

- Toyota Yaris 2012

- Tree, Calamondin Orange

- Tree, Meyer Lemon

- Tree, Persian Lime

- US Bill of Rights

- US Constitution

- US Declaration of Independence

- UV Vodka

- Weight on other Planets

- Wicca Pages

- Wine Clubs

- Wines

- Wines - Missouri

Needed to read PDF's

Work Boots

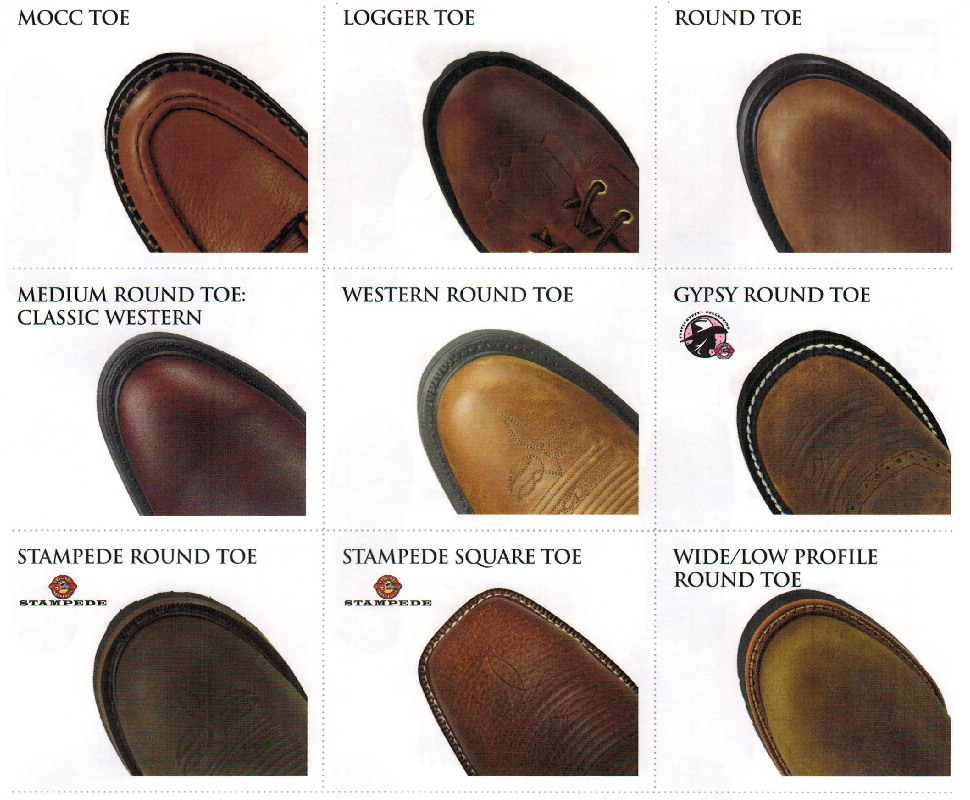

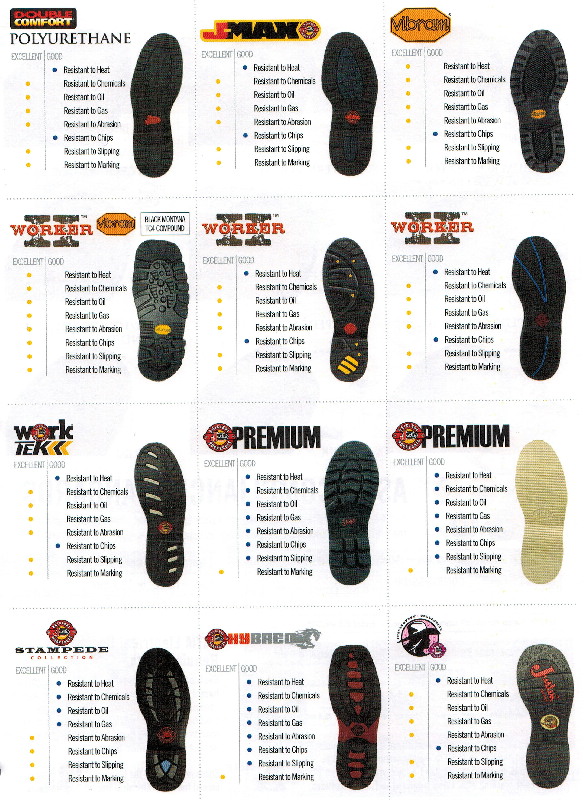

Soles, Toes & Heels

How to Choose Work Boots

One of the worst feelings? Tired, achy feet after a long day of hard work. Even worse than that? Foot pain as a result of not having the right protection on the job. That's why having the right work footwear is critical. And if you need help with the overwhelming task of picking the perfect pair? Well, that's where we come in. This guide will walk you through the components, features and considerations for finding the style to suit your occupational needs. You never know what your shift will bring, but at least you can be confident your boots can handle it.

Toe Types

When it comes to selecting work boots, knowing what toe type is right for you is one of the most important factors. Impact injuries are serious, and the right footwear can keep you protected. With many different safety toe types available, you'll want to weigh the pros and cons before selecting the boots you'll trust to guard your feet. There are many trade-offs you'll need to consider; a higher level of protection may cost you dexterity and comfort.

- Soft Toe Work Boots Soft toe boots are extremely lightweight and comfortable. If your occupation has a low risk of impact injuries, and no safety toe requirement, these will be the most comfortable. Since there is no safety toe box, soft-toe work boots will have a slimmer silhouette and a lower price tag.

- Steel Toe Work Boots Steel toe work boots offer heavy-duty protection against harsh blows. They are strong and durable but as they are metal, will conduct heat or cold. They are popular as they are economic, as well as effective against crush injuries. The main drawback to a steel toe safety boot is it's not as light as other options. Steel toe caps typically weigh a fifth of a pound, which can really weigh you down on a long day.

- Composite Toe Work Boots Made of non-metal materials like kevlar, carbon fiber, plastic, or fiberglass, Composite toe caps are lighter than steel toe caps and won't conduct heat or cold. Since they are nonmetal, they are airport friendly. However, in order to meet the same impact resistance safety ratings as metal, composite toe boxes have to be thicker. As a result, they have a bulbous appearance some don't find aesthetically pleasing.

- Alloy Toe Work Boots Alloy safety toe boxes are made up of a mix of metal, typically aluminum and titanium. They can be up to 50% lighter than steel, but just as strong with a little more room in the toe box. You get what you pay for — they may be slightly more expensive than other safety toe types.

- Aluminum Toe Work Boots Aluminum safety toe footwear is an excellent choice for those who need light and agile footwear. It still provides protection but is lighter than steel and not quite as bulbous as composite toe footwear.

- Met Guard Work Boots A met guard extends the protection past the toe, all the way to the ankle. Met guards can be internal or external and form a box around the foot to guard against compression. Met guards are popular for welders as they protect more of the foot (and laces) from the sparks and flames that come with the job.

Components

Upper

The upper refers to the part of the shoe that wraps around your foot, sometimes extending up to the ankle or calf. The durability, stability and look of the boot is all directly related to the material used in the upper.

Full-grain leather: Not all leather is created equal. There are many different types of leather, ranging in different levels of quality. When searching for a rugged pair of leather boots, look for the full-grain callout. Full grain leather is considered the highest quality of leather because it contains the entire grain of leather without anything removed. Instead of succumbing to wear-and-tear, it develops a handsome sheen. It's durable, good looking and ages exceptionally well.

Split-grain/suede leather: Split-grain leather is another great choice to look for. Made from the flesh-facing portion of a cattlehide, it's thinner and softer than full-grain leather. It's not waterproof or as supportive as full-grain leather, but it is lightweight and more breathable. You'll often find it paired with nylon or mesh to reduce the overall weight of a work boot or shoe.

Nubuck leather: Made from the outside portion of a hide, nubuck leather is similar to full-grain leather, however, is buffed to look like suede. It gives the fuzzy look and feel of suede that many favor aesthetically, without sacrificing much durability. Supportive, water-resistant and abrasion resistant, it's a great choice if you want rugged work boots that have a stylish look and flexible feel.

Genuine leather: When it comes to leather, you get what you pay for. Genuine leather is less expensive than other leather options. However, it's one of the poorest grades of leather. An item made of genuine leather is simply made of animal leather (as opposed to synthetic leather). It's often produced from leather scraps or leftovers.

Synthetics: While synthetic materials are not as durable as leather, they boast the huge benefit of how little weight they add to your feet. These materials, such as nylon and polyester, are known for the comfort and breathability they bring to work footwear. Not only are synthetic work boots generally lightweight and easy to break-in, they also allow you to be quick on your feet. If your job requires agility over durability, footwear crafted from synthetic fabric is the way to go.

Midsole

The midsole encompasses the area between the outsole and the upper. As you can imagine, this component plays a big part in determining comfort. Read about common midsole materials below to find the right fit underfoot.

Ethylene Vinyl Acetate (EVA): EVA is one of the most common midsole materials found in work boots. Comfortable and compression-resistant, EVA can help ease foot pain. It will break down and lose form over time, but an aftermarket insole can fix that.

Polyurethane (PU): Polyurethane is denser and heavier than EVA. As a result, it will keep its form over a longer period. They tend to be pricier than EVA midsoles. Consider a PU midsole to avoid wear and tear in your boots.

Shanks: A shank is a plate, usually made from metal, embedded into the midsole of a boot. They offer puncture resistance as well as balance and stability.

Outsole

The outsole is the part of your footwear that makes direct contact with the ground. The type of outsole on your boot can protect you from hazards such as puncture wounds, as well as give you the traction and composure you need on an uneven or slick surface.

Rubber: Rubber is a common outsole material. Grippy, flexible and ideal for working around electrical hazards, rubber outsoles hold their form and offer unparalleled traction on uneven surfaces. One of the most popular outsole types is Vibram. Vibram makes a proprietary rubber blended with a springy foam, and its outsoles can be found on the top work boots styles across many iconic brands.

Lug / tread patterns: Lugs are the grooves and indentations on the bottom of outsoles. The tread pattern of your footwear can greatly affect your performance. Large, wide lugs add stability and durability. Small lugs are excellent for shedding mud and debris while working outside.

Slip resistance: For many labor-intensive occupations, such as restaurant employees, mechanics and construction workers, slip-resistant footwear can prevent a workplace accident. Slip-resistance outsoles have been tested for adhesion and resilience. Look for this safety rating to stay stable and surefooted.

Features

Work Boot Types

- Electrical Hazard Safe Work Boots Working with live wires is dangerous and unpredictable. Electric hazard safe work boots are engineered to insulate your feet, adding another layer of protection against electrical injury. Look for the acronym EH next to the ASTM safety rating. EH-rated footwear can protect the wearer from up to 600 volts in a dry environment.

- Water Resistant Work Boots Water-resistant boots, also referred to as water repellant, have a coating or natural ability to repel moisture away from the surface, rather than absorbing it. They will not stop water from entering the boot, especially if the boot is submerged.

- Waterproof Work Boots Waterproof boots are a necessary feature when it comes to maintaining your comfort, especially when working outdoors. Not to be confused with water-resistant footwear, which just repels water away from the shoe, boots classified as waterproof will also keep water out of the interior while pushing sweat and moisture out.

- GORE-TEX Work Boots Waterproof boots are sometimes synonymous with GORE-TEX. While it's not the only waterproofing technology available, it's one of the most frequently marketed. GORE-TEX technology is typically an internal membrane that works to keep water out. However, it only works as far as the membrane reaches, which usually ends before the ankle. Also, this membrane can make it stuffy and warm inside the boot.

Insulated Work Boots

Chilly worksite? It's hard to focus on the job when your feet are frozen. That's where this feature comes in handy. Insulated boots are typically lined with Thinsulate, a synthetic fiber that will block cold air and keep feet toasty. Thinsulate is measured in grams and ranges from 200G to 1000G. The higher the number, the more insulated the boot. So which level is right for you?

- 200 grams: Recommended for cool conditions or high activity levels. It's ideal for putting in overtime during the cooler summer nights.

- 400 grams: Recommended for cold conditions or moderate activity levels. This amount is perfect for working outside in the fall.

- 600 grams: Recommended for very cold conditions. Once the first snow falls, this amount is great for keeping feet warm.

- 800 grams: Recommended for extremely cold conditions with light activity levels. We would suggest this amount for wintery conditions on the job.

- 1,000 grams: Recommended for extremely cold conditions with light to minimal activity level. It's excellent for maneuvering through snow and ice.

Safety Work Boots

- Heat Resistant Work Boots Some jobs are so precarious you need all the protection you can get. Heat-resistant boots are safety rated to withstand high temperatures while insulating your feet from the danger. This feature is ideal for roofers, welders and construction workers that are likely to come across dangerous temperatures. If you see that heat-resistant label, rest assured it was tested to perform on high heat surfaces.

- Puncture Resistant Work Boots Rusty nails, broken branches and pointy debris are all no match for puncture-resistant work boots. Puncture wounds are some of the most common (and awful) of possible foot injuries on many job sites. These outsoles not only provide excellent traction, they also prevent sharp objects from reaching your feet.

- Chemical Resistant Work Boots From the plant to the farm, many labor intensive jobs include substances you just don't want on you; Substances such as fertilizers, ammonia, pesticides, wet concrete, animal waste and more. Despite best intentions, leaks, spillage and otherwise unwanted contact can be all too common. Chemical-resistant footwear is essential for any position that involves hazardous — or even just plain gross — material. Chemical resistance ratings are based on degradation and permeation.

- Postal Approved Footwear The U.S. postal service is selective about what footwear it allows its employees to wear. Avoid purchasing pitfalls by browsing our extensive list of postal-approved footwear. Each style is crafted to not only meet regulatory requirements, but to provide optimal cushioning.

- Removable footbeds This feature may seem inconsequential, but the ability to customize your comfort underfoot cannot be understated. Removable inserts typically have quality cushioning technology to help absorb the force of your weight with every step.

Styles

- Western Work Boots Everyone loves a good pair of cowboy boots. This footwear is so popular they transcended their original purpose. Created for riding and grueling ranch work, the style evolved to become an icon for the western way of life. Despite being adapted for fashion, western boots hold up to hard work like no other. Characterized by luscious stacked leather, a slight heel and a high shaft, western footwear provides much needed durability and stability.

- Wellington Work Boots Wellington boots can be identified by their pull-on entry, designed to conveniently throw them on before work and kick off after your shift. While many equate the term wellington with rubber muck boots, the name can also refer to durable leather pull-on work boots. Wellingtons typically boast a high shaft and pull straps, ideal for protection against water, mud, grime and snow. Keep your feet warm, clean and dry and let your wellingtons take the brunt of the work day.

- Wedge Work Boots Known for their classic look and exceptional traction, wedge work boots have been an American staple for more than a hundred years. That long-standing history speaks for itself. You can identify these boots by their signature white outsole, which provides comfort as well as stability. The beauty of a classic pair of wedge boots? They pair just as well with a button down as they do with a t-shirt.

- Lace Up Work Boots (logger & lineman) The preferred choice of lineman and loggers, lace-up work boots are a popular choice for those whose main priority is stability. The tall heel is ideal for climbing and provides much needed arch support.

- Athletic Work Shoes Athletic work footwear not only takes cues from popular running shoes and sportswear, but many are also made from the very same manufacturers. Brands such as Reebok and Skechers blend the fitness-focused features they are known for with safety features that offer protection on the job. They are typically made from lightweight synthetic materials, which lessen foot fatigue and increase agility. This style is ideal for warehouse workers, delivery drivers and jobs that require you to be quick on your feet.

- Casual & Dress work shoes Some job sites require an elevated, professional appearance. Casual and dress work shoes pair well with slacks and more formal attire. Despite the dressy look, these styles often contain protective features, such as safety toe boxes and slip-resistant outsoles. An added bonus? They transition seamlessly on-the-clock to off.

Fit Tips

The following tips will help you get that perfect fit.

Use a Brannock device The best way to determine your foot size is by using a Brannock device (an oblong, ovular tool with sliders to measure the length, width and arch of your foot). Use one to find the exact measurements of your feet, which will be useful when choosing your size. Size is determined by the length of your foot and is different for men and women.

Find Your Width Most work footwear will come in various widths, from "extra narrow" (B) to "triple wide" ("EEE"). However, these width classifications aren't always consistent. Brands will classify widths differently, so it is important to check your measurements against the conversion chart for each style.

Consider a brand you're familiar with Each brand is different. However, they tend to make their own footwear fit consistent across their whole line. If there is a brand you have worn before and like, chances are other footwear from the same brand will have a similar fit.

Try your boots on in the afternoon Throughout the day, our feet take on enormous pressure. By late afternoon, your feet will have swelled a significant amount. To avoid buying footwear that becomes uncomfortably snug by the end of the day, try boots on at the end of the day.

Socks When you try any footwear for the first time, you should wear the socks you plan to wear consistently. The material, thickness and feel of your sock can really affect the way your feet fit and feel in your boots.

Try aftermarket insoles Comfort is not something to compromise on. Aftermarket insoles really go the extra mile when it comes to personalized fit and comfort. They might also add the right touch of snug to loose boots.

General Fit It may seem like common sense, but your toes shouldn't be pressed against the tip of your boots and heels should not slide around — you'll end up with blisters if they do. Be sure to walk around in your boots and make sure your heel is not rubbing the insole as you walk. Make sure your toes have room to splay and aren't squeezed together. Before purchasing, keep in mind that safety toe boxes will take up a bit of space, so if you are in-between sizes, size up. Remember that if it's mildly uncomfortable during an initial try on, whether that be too much space or too little, this will only be exacerbated while wearing for a longer duration.

Breaking In Not all work footwear is comfortable right out of the box. Stiff leather and responsive insoles will often take a break-in period before they adjust and conform to your foot shape. It's always recommended to spend time walking around in your boots before you wear them on the jobsite.

Your work boots are the very foundation of your day. With every step, your footwear absorbs the weight of your body. Labor-intensive occupations put even more stress on your footwear — not to mention the added jobsite hazards like potential impact, electrical and puncture injuries. The guidance above, paired with some research and due-diligence, will help you find a pair up for the challenge.

Work Toe Styles |

Work Sole Styles |

Lacing Patterns for Wesco Lace-up boots

Wesco lace-up boots are available with three kinds of lacing patterns. These lacing patterns influence both the number of lacing eyelets below the lacing hooks and the way the boots are sewn together in the foot.

|

|

|

| Lace-to-toe Regular Toe / Optional Safety Toe | Semi-Lace-to-toe / Optional Safety Toe |

The difference in the lacing styles lies in how far the lacing eyelets extend towards the toe and how the vamp or foot area is sewn.

The regular-toe style has 4 eyelets extending towards the toe from the bottom lacing hook, the semi-lace-to-toe style has 5 eyelets and the lace-to-toe style has 6 eyelets.

The eyelets are spaced one inch (2.54 cm) apart. A 10 inch regular toe boot has 4 lacing eyelets at the toe, 5 lacing hooks going up the leg and a final lacing eyelet at the top. The 10 lacing positions, each one inch apart, give the boot it's 10 inch designation, but the boot is actually about 9 inches tall (measured up the inside back from the sole to the top).

Safety toes are compatible with regular and semi-lace-to-toe styles but not with the lace-to-toe style.

Features of each lacing style:

|

Lace-to-toe: 6 eyelets at the toe Not Safety toe compatible Seam where top attaches points up Fit of the toe more adjustable |

Regular Toe: 4 eyelets at the toe Safety toe compatible Seam where top attaches points down Fit of the toe not adjustable |

Semi-lace-to-toe: 5 eyelets at the toe Safety toe compatible Seam where top attaches points up Fit of the toe slightly adjustable |

The issue with the way the top attaches is important in that the regular toe boot seam points down, as you can see in the above photos, and it will tend to snag on short sticks or branches pointing up from the ground. The lace-to-toe and semi-lace-to-toe styles have the seam where the top joins pointing upwards. That means that branches or sticks will slide past the seam without snagging.

False Tongue / Kilty

|

|

Find me on Social Media

|

Don't forget to bookmark me to see updates.. Copyright © 2000 - 2025 K. Kerr Most recent revision July 26, 2025 11:50:43 AM

**DISCLAIMER: THIS WEBSITE DOES NOT PROVIDE MEDICAL ADVICE: The information, including but not limited to, text, graphics, images and other material contained on this website are for informational purposes only. No material on this site is intended to be a substitute for professional medical advice, diagnosis or treatment. Always seek the advice of your physician or other qualified health care provider with any questions you may have regarding a medical condition or treatment and before undertaking a new health care regimen, and never disregard professional medical advice or delay in seeking it because of something you have read on this website. |